OUTSOURCED MANUFACTURING

Powdered Metal

WHO WE ARE

Why Choose IC Sales for Powdered Metal Parts?

From an array of industrial, automotive, and healthcare applications to small, niche market projects, IC Sales has the experience and precision technology needed to produce cost-efficient powdered metal component parts that meet your exact specifications. Oh, and we make everything right here in the United States.

From onboarding and quotation to production and packaging, we’ll work with you to ensure your component parts are produced on time and up to spec. That’s our promise.

What’s Powder Metallurgy?

Fine metal powders are compacted into a near net shape. Parts are sintered in a controlled atmosphere furnace to fuse the powder particles into a dense solid. Powdered metal offers low cost tooling, zero draft capability on vertical walls, minimal material waste, low energy usage and competitive pricing. Powder metallurgy is the perfect solution for a wide range of applications.

Materials

Powdered Metal Materials

Typically brass parts are molded, sintered and “sized” which involves a second pressing operation. Sized brass is higher density and provides increased strength and tighter dimensional control. Due to its resistance to corrosion, powdered brass is ideal for components that may be exposed to liquids. Brass and bronze can be infiltrated with oil for bushing and bearing applications that require self lubrication.

Valued for its thermal and electrical properties, powdered copper is used in heat sinks, connectors, terminals, valves, and components for thermal systems.

High purity iron can create particular alloys, making it ideal for many automotive and magnetic component applications.

Powdered stainless steel allows for precise, lower waste components without sacrificing strength or quality.

For structural strength, powdered metal aluminum blanks are forged in a secondary process. This increases density, strength and dimensional control. Automotive engine connecting rods are a prime example.

Copper steels offer improved ductility. Nickel steel offers excellent wear resistance. Carbon steel for added strength and hardness.

Common Applications

Powdered Metal Applications

Due to the precision, efficiency, and affordability of Powder Metallurgy, it’s a go-to choice for many applications.

Automotive

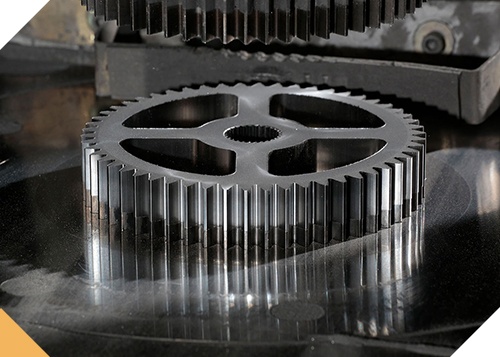

Great for gears, shifter and clutch parts, bearings, bushings, chassis components, and other structural parts.

Aerospace

Reduce the cost and weight of components traditionally produced through machining or other processes.

Healthcare & Technology

A high degree of control over the composition and magnetic properties makes components well suited for applications with magnetic and reactive properties.

Home Goods

Great for small engine parts like knobs, housings, latches, bearings, gears and specialty fasteners.

Types of Powder Metal Processes

Powder metal processes use fine metal powder as a base material, which we can then compact, inject, forge or 3-D print to produce a precise finished component.

Press and Sinter Powder Metallurgy: The base material is compacted in a hydraulic press to form a green blank. The blanks are then sintered and fused in a controlled atmosphere furnace, producing a precise finished component.

Metal Injection Molding: Super fine metal powder is encapsulated with plastic and molded into a shape with conventional injection molding machines. Parts are sintered in a controlled atmosphere furnace resulting in a 97% dense solid component with highly complex shapes.

Machine Powder Metal Parts: IC Sales is a full service custom part provider, and we can provide secondary machining for the most difficult to produce components.

Additive Manufacturing / 3D Printing: High-resolution 3D printing produces dense, high-quality parts capable of performing in the most demanding applications.

Have questions about Powder Metallurgy? Are you exploring various manufacturing methods to achieve your product goals?

With over 30 years of manufacturing experience and service, we’re confident that we can provide you with exactly what you need to meet your product specifications and production deadlines.